3D head is a device that extends the existing cutting capabilities on a perimeter.

The device enables smooth deflection of the plasma torch from the right angle during operation of the plasma cutter using servo drives with gearboxes with very small clearance tolerances. The device is controlled digitally using the RTF (Real Time Follow) function, which in real time controls all cutting parameters, including plasma arc voltage settings, pressure settings and plasma gas flows. RTF is necessary to perform the correct welding phase.

Advantages of 3D Head

- Angle of inclination +/- 45 °

- Rotation angle +/- 540 °

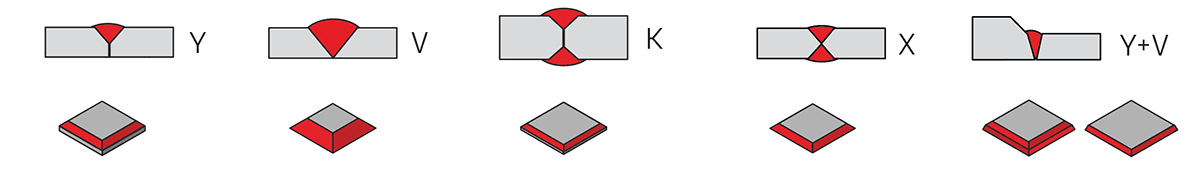

- Bevelled firing of all welding phases V, X, Y or even K

- Burning pipe joints

- The possibility of imposing welding phases directly from the controller (without additional software)

- Can be exchanged with a torch for perpendicular cutting (when not in use)

- It is possible to add each of our power cutters at any time (without prior preparation of the machine)

- Adapted to work with any type of plasma source: 130A, 260A and 460A

Welding phases